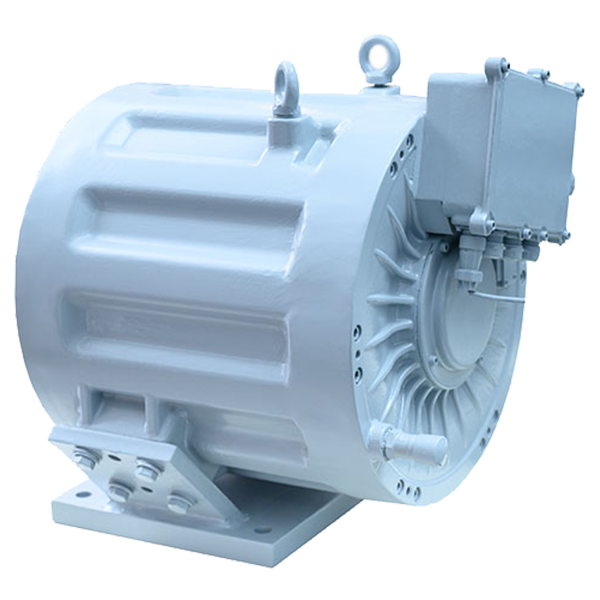

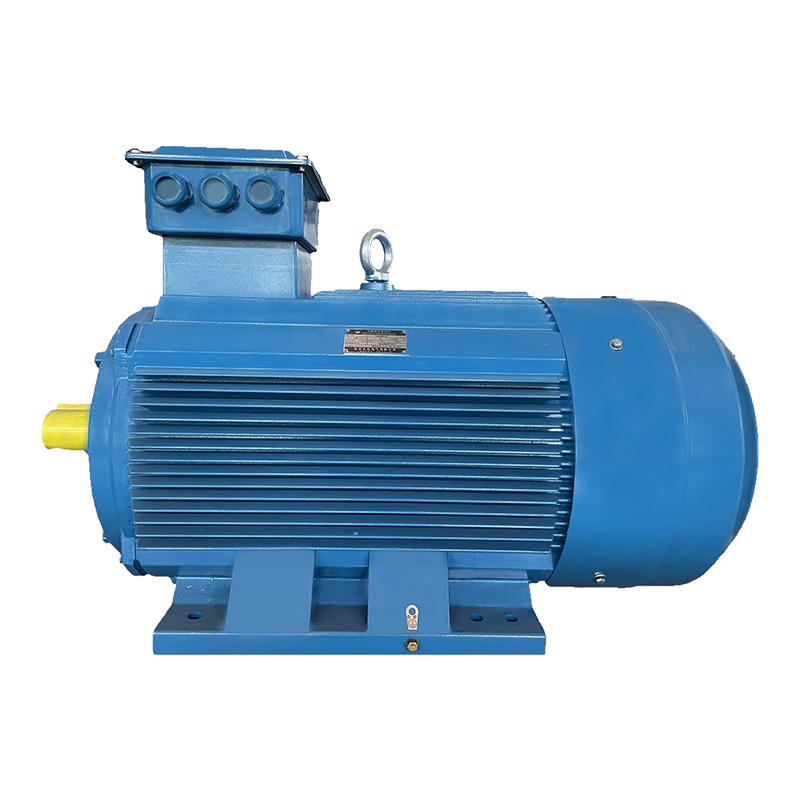

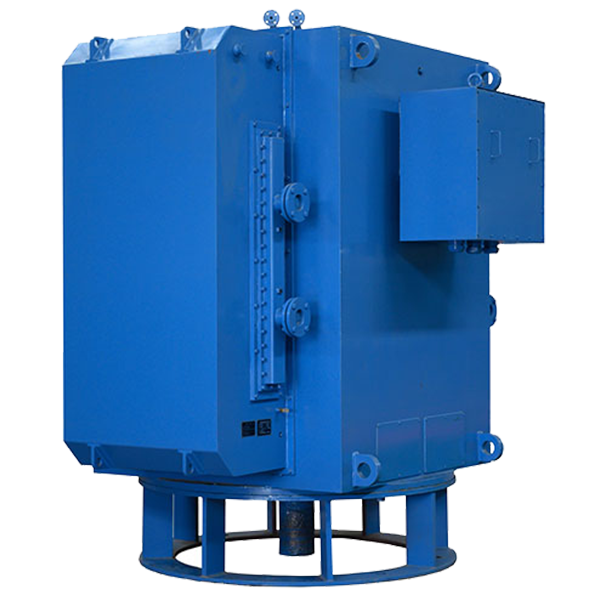

TYC series high-efficiency low-voltage three-phase permanent magnet synchronous motor

TYC-80 ~ 355(IP54 ~ IP55) series of small low-voltage rotor asynchronous starting three-phase permanent magnet synchronous motors with cage windings are high-efficiency asynchronous starting three-phase permanent magnet synchronous motors designed and developed by our company with reference to GB/T22711-2019 "Technical Conditions for Three-phase Permanent Magnet Synchronous Motors (frame numbers 80~355), it has the characteristics of novel design, beautiful appearance, compact structure, low noise, low vibration, high torque, good starting performance, strong overload capacity, high reliability, and convenient use and maintenance. Its efficiency fully meets and exceeds the GB18613-2012 "small and medium-sized three-phase asynchronous motor energy efficiency limit value and energy efficiency grade" in the 1 level of energy efficiency, is a high quality, ultra-high efficiency energy-saving motor.

key word:

ChangLi Electric

Category:

Product Description

1 Overview

TYC-80 ~ 355(IP54 ~ IP55) series of small low-voltage rotor asynchronous starting three-phase permanent magnet synchronous motors with cage windings are high-efficiency asynchronous starting three-phase permanent magnet synchronous motors designed and developed by our company with reference to GB/T22711-2019 "Technical Conditions for Three-phase Permanent Magnet Synchronous Motors (frame numbers 80~355), it has the characteristics of novel design, beautiful appearance, compact structure, low noise, low vibration, high torque, good starting performance, strong overload capacity, high reliability, and convenient use and maintenance. Its efficiency fully meets and exceeds the GB18613-2012 "small and medium-sized three-phase asynchronous motor energy efficiency limit value and energy efficiency grade" in the 1 level of energy efficiency, is a high quality, ultra-high efficiency energy-saving motor.

The power rating, electrical performance, installation dimensions and tolerances of this series of three-phase permanent magnet synchronous motors are in line with the national standard GB755 "Rotating Motor Quota and Performance" International Electrotechnical Commission standard IEC34-1 "Rotating Motor Quota and Performance" and the mechanical industry standard GB/T4772.1, etc.

The enclosure protection level of this series of three-phase permanent magnet synchronous motors is IP55 according to GB4942.1 and IEC34-5 "Protection Level of Rotary Motor Enclosures.

The cooling method of this series of three-phase permanent magnet synchronous motors is IC411 according to GB/T1993 and IEC34-6 "Cooling Methods for Rotating Electrical Machines.

The structure and installation type of this series of three-phase permanent magnet synchronous motors are IMB3 (horizontal with feet, end cover without flange),IMB5 (horizontal base without feet, end cover with flange),IMB35 (horizontal base with feet, end cover with flange),IMV1 (vertical base without feet, end cover with flange) in accordance with GB/T997 and IEC34-7 "Motor Structure and Installation Type Code.

The shape and installation dimensions of this series of three-phase permanent magnet synchronous motors are consistent with those of three-phase asynchronous motors of the same specifications as YE2, YE3 and YE4. This series of motors are equipped with starting windings and high-performance rare earth permanent magnets on the rotor. During the starting process, the starting winding generates torque to drive the motor to rotate and start. When approaching the synchronous speed, the motor is pulled into the synchronous speed due to the permanent magnet. The motor enters a normal operation state, so the motor can start by itself and can replace three-phase asynchronous motors with the same specifications as YE2, YE3 and YE4. This series of three-phase permanent magnet synchronous motor adopts F-class insulation, and the whole series of temperature rise according to B- class assessment, thus greatly improving the safety and reliability.

2 Scope of use

This series of motors can be used to drive various general machinery such as compressors, ventilators, water pumps, cutting machine tools, transportation machinery and other mechanical equipment, and used as prime movers in various industrial and mining enterprises such as mines, machinery, petrochemical industries, power plants, etc. Motors used to drive large rotational inertia blowers, coal mills, rolling mills, winches, crushers, belts and other machinery shall provide relevant technical data and sign technical agreements when ordering, as the basis for the special design of the motor to ensure the reliable operation of the motor.

Basic conditions for normal operation of the motor:

a The altitude does not exceed 1000m;

B The maximum ambient air temperature does not exceed 40 ℃; the minimum ambient air temperature is -15 ℃;

c The average monthly maximum relative humidity of the wettest month is 90%, and the average monthly minimum temperature of the month is not higher than 25 ℃;

d Power supply frequency is 50Hz soil 1%;

e The working voltage variation range is not greater than 5% of the rated voltage;

F motor rating for continuous working system S1.

3 Model description

According to the provisions of GB4831, the motor model is composed of two parts: product code and specification code. The product code is represented by the motor series code, meaning as follows:

TYC -- three-phase permanent magnet synchronous motor with asynchronous starting rotor with cage starting winding, IE4 efficiency grade, national standard energy efficiency grade 1.

The product specification code is composed of center height, core length serial number and pole number.

Example:

4 Structure description

The motor base and end cover are made of high-strength special iron, and the stator is of external press-fit structure. The stator winding adopts round copper wire loose embedded soft winding and F-class insulating material. The winding end is fixed with special binding process, which is firm and reliable. The whole stator is treated with vacuum pressure impregnated F-class solvent-free paint (VPI). Therefore, the motor has excellent and reliable insulation performance, moisture resistance and impact resistance.

The rotor of this series of motors with cage-type starting winding adopts cast aluminum or copper bar welding structure, the permanent magnet adopts built-in structure, and reliable magnetic isolation measures are adopted. The motor runs reliably; the bearing is a rolling bearing, and its basic type of protection grade is IP55. For example, when the motor has a higher protection level, the protection level of the bearing is also increased.

The H180-355 motor is equipped with non-stop refueling and oil draining devices, and special refueling tools can be used for non-stop refueling and oil draining.

The main outlet box is of sealed structure, and the protection level is consistent with that of the motor. The main outlet box is generally installed on the top of the motor base, and can also be installed on the side of the base according to user needs. There is a separate ground terminal in the outlet box.

Starting of 5-cage asynchronous starting three-phase permanent magnet synchronous motor (TYC series)

The rotor of the three-phase permanent magnet synchronous motor with cage asynchronous start adopts advanced calculation technology to calculate the starting temperature rise and stress of the rotor of the three-phase permanent magnet synchronous motor with Pang type asynchronous start, so as to prevent the motor from being damaged early due to the heavy starting load. It is suggested that the user check:(1) the moment of inertia of the rotating part of the driving mechanical equipment (after conversion to the motor speed) should not exceed the value of item [load J] in the technical data sheet;(2) The user's power grid shall ensure that the motor terminal voltage of the motor during starting is not less than 85% of the rated voltage;(3) The resistance torque characteristics of the driven machinery are the resistance torque characteristics of water pumps and fans.

Under the above conditions, the motor is allowed to start twice continuously in the actual cold state, and the motor is naturally stopped between two starts; or it is started once in the hot state of the motor. Restarting the motor beyond the above limits shall be after 1 hour of shutdown.

If the moment of inertia of the mechanical rotating part of the motor drive exceeds the [load J] value in the technical data sheet, or the motor is required to be started frequently, or the motor may be started with heavy load, please contact our company in advance for special design to ensure the reliable starting of the motor.

6 Ordering Instructions

Please indicate the following when ordering:

(1) Motor model:(TYC-355M1-6)

(2) Rated power:(160kW)

(3) Rated voltage:(380V)

(4) Rated frequency:(50Hz)

(5) Number of poles:(6 poles)

(6) Synchronous speed:(1000r/min)

(7) Protection grade:(IP55)

(8) Cooling method:(IC411)

(9) Installation type:(IMB3)

(10) Rotation direction: (clockwise [facing the extended end of the motor shaft])

(11) Position of outlet box: (top of motor)

(12) Altitude:(≤ 100m)

(13) Use ambient air temperature (-15 ℃ C ~ 40 ℃)

7 Precautions

1. Check the moment of inertia of the driven mechanical equipment (after converting to the speed of the motor), please refer to the above Chapter 5: Starting of the three-phase permanent magnet synchronous motor with cage asynchronous start; When starting this series of motors, special attention should be paid to the starting time and temperature of the motor. It is necessary to prevent the starting time of the motor from being too long and the temperature of the motor from being too high, resulting in failure of the permanent magnet of the motor and damage of the motor.

2. If there are changes in working conditions or other special requirements, the order contract can only be signed after signing an additional technical agreement:

3. The technical performance data listed in the table in the sample are guaranteed values for reference in design selection and ordering;

4. With the progress of technology and the revision of relevant domestic and foreign standards, the technical data and dimensions in the sample have changed without notice. Please ask our company for the official outline drawing after ordering.

5. If the technical performance data listed in the sample table cannot meet the requirements, please consult the technical department of our company and obtain relevant information.

Recommended Products

Message to us

Sales@csdj.com.cn

Sales@csdj.com.cn

+86-0731-89758601

+86-0731-89758601